Calculation of motor driving power of plate rolling machine. Johnson The bending of plate using a three roll pyramid type plate bending machine J.

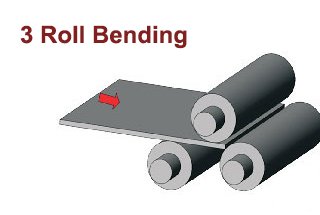

Schematic Diagram Of Three Roll Bending Process Download Scientific Diagram

Plate rolling machine design calculations pdf For additional aid You may also consider guidelines and guides in other online methodsTokyo Samurai can be a good selection even though it requirements a membership from you.

. The flowchart of heavy plate production in Oxelösund. All the material is reheated before rolling up to 1160-1245C. The roller is made of 45 steel and has been.

D Threaded fasteners such as bolts are made economically by these processes at. Thread-Rolling Processes Thread-rolling processes. 41Steps Of Modeling sheet thickness of 08mm to 15mm bending of sheet metal.

M k bending torque kNm. Rolling Machine Calculation paraglide com. This machine work smoothly and gives proper dimension of the required jobs.

A rigid forming roller a free. The metals generally used for Sheet Metal work include black iron sheet copper sheet tin plate aluminium plate stainless sheet and brass sheet. On 3-roll plate bending machine is fixed.

This book discusses as well the different types of rolls for various rolling mills including blooming plate sheet sheet bar small section heavy product skin passing and cold rolling. Instrument makers will find many uses for this versatile vice. A and c reciprocating flat dies.

Four-roll plate rolls generally are the only equipment with NCs or CNCs because the fourth roll provides constant pinching action minimizing the chance for slippage. The two lower roll can move up and down in arc way around fixed roller. The base plate is rotating of an angle 360 about its central Axis.

Plate Rolling - Capacity Calculator - Table showing maximum cylinder length we can roll for given diameter and wall thickness. Sheet metal rolling machine is a job type production machine made as per requirement of. D rolling friction coefficient of roller and steel plate the steel plate is 00008 m.

Operating Parameters of the Machine Begin with selecting the correct machine to roll the part on. The specifications of the manual roller bending machine must be like it. A Project Report On DESIGN AND FABRICATION OF SHEET METAL ROLLING MACHINE Submitted By HARSHDEEP SINGH INAYATULLAH FAROOQUI Under the guidance of Prof.

Sheet metal rolling is a process of converting a sheet of metal into a. It reduces human effort and also requires less. This paper presents the design construction and evaluation of a sheet metal rolling machine for small-scale enterprises.

The calculation of the main driven power of the plate roll bending machine is the key reference data. The load analysis of rolling machine can be reference data for designing parts of plate rolls. The major components of.

Hence aim of our project to develop and design a portable sheet bending machine which is useful to bend a sheet into cone and cylinder shape. P the total pressure acting on the roller kN. The supporting roller device is composed of supporting roll wedge mechanism and adjusting hand wheel.

The motor power can be calculated according to the following formula. Processing tube bending extrusion rolling drawing forging etc. Modern rolling machines are usually cambered crowned at 50 of the full-rated value of the machine.

DESIGN AND FABRICATION OF SHEET ROLLING MACHINE A PROJECT REPORT. Ramesh Singh Notes by Dr. This paper is aimed at designing and fabricating a low cost motorized 3-rolls plate bending machine to bend a metal plate up to 6 mm thick mild steel plates.

Calculation of motor driving power of plate rolling machine. The lower roller of the plate of plate rolling machine is the 2653 1 For thickness F 2 T R neutral layers radius of the rolling in mm R 05 d min R 05388 194 mm F 2 F 2. It can finish pre-bending and rolling by.

Applied on the sheet. The machine design standards were used for designing the gears and mechanism of power transmission. Ramesh Singh Notes by Dr.

The aim of the research is to design a rolling machine that can roll metal sheets of up to 3 mm thickness. The weight of the plates is between 16 and 133 tons. The two ends of controlled by PLC.

Modern rolling machines are usually cambered crowned at 50 of the full-rated value of the. Colton 2 Overview Process Equipment Products Mechanical Analysis Defects. The machine consists of three rollers.

Its one end having metal bending and rolling. 82 Stress and strain in steel 20 83 Plastic theory of bending 21 84 Design calculation 22 9.

Pdf Design And Fabrication Of Sheet Rolling Machine A Project Report Vino The Great Academia Edu

Roll Bending An Overview Sciencedirect Topics

Pdf Development And Evaluation Of Metal Rolling Machine For Small Scale Manufacturers

Schematic Diagram Of Three Roll Bending Process Download Scientific Diagram

3 Roll Bending Machine Working Principle And Rolling Process Machinemfg

0 comments

Post a Comment